A large truck manufacturer from Sweden was looking for a facility to increase their blasting capacity.

The customer felt it was important that the production process not be disrupted by a long blastroom build-up and the associated inconvenience. Our turn-key innovative blastroom concept was chosen. The blastroom is fully assembled in our factory, tested and accepted by the customer. The hall is then transported to the customer by special transport and commissioned on site in three days by our skilled personnel.

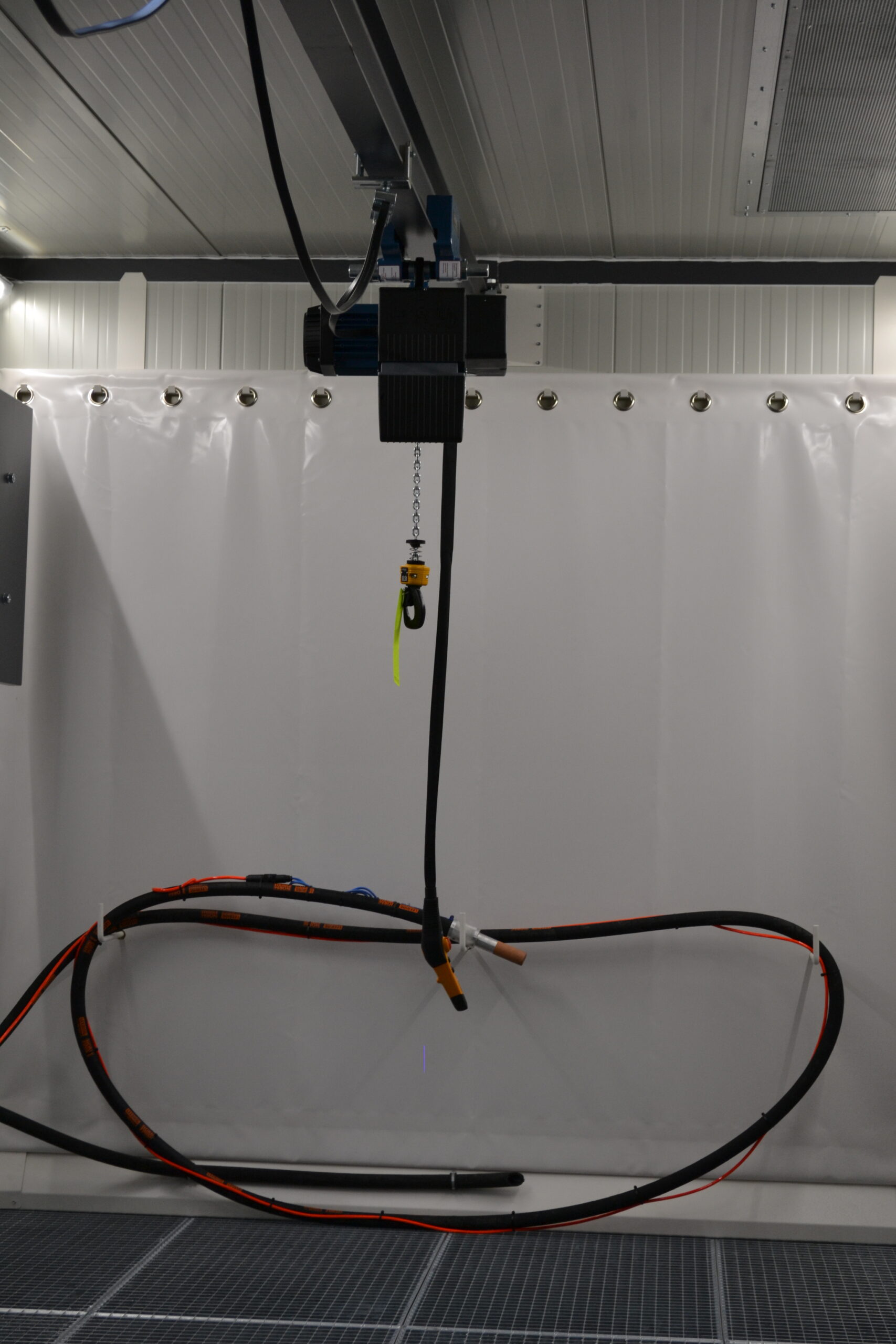

The facility, with all equipment integrated, was equipped with a scraper floor, eliminating the need for sweeping after blasting. By means of a monorail outside, and inside the blastroom, equipped with electric hoist, products of up to 400 kg can be easily transported in and out of the blastroom.