Depowdering

Depending on the material type of the 3D printed product, the post-processing, Depowdering, differ. The product properties of polumersrequire a different way of finishing than metal. Depending on the desired surface properties a choice will have to be made when Depowdering.

In general, the process of removing powder, also called Depowdering, is unavoidable for all powder bed printed products.

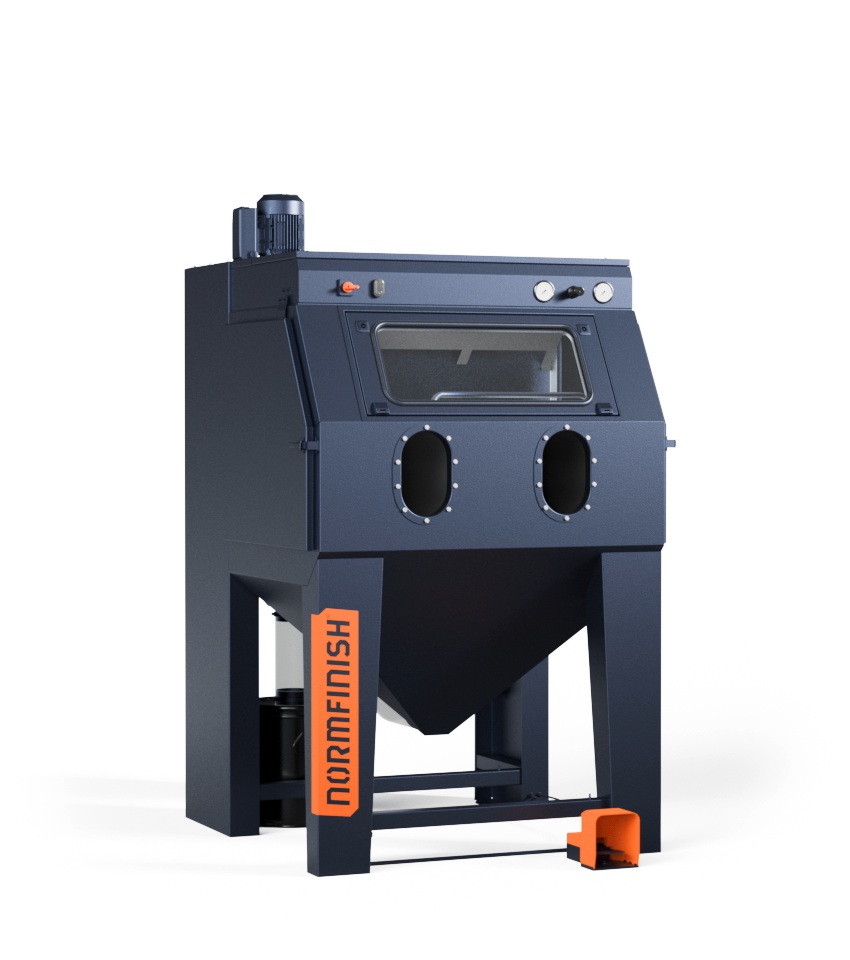

For 3D printed products printed using a powder bed printing technology, a blast principle is used in most cases. Here there are many choices. Normfinish has selected the best options for you and offers them in a special range of blast cabinets for Post-processing.

Depending on the dimensions, geometry, quantities and material, a manual or automated process can be chosen. In recent years, automated processes have particularly been in demand. This is explained by the fact that 3D printing volumes are increasing rapidly and automation saves a lot of labour costs. Automation ensures repeatable quality and better process reliability.

Normfinish offers a standard range of automated blast cabinets, the Normfinish 3D series, consisting of the 3D Solid Clean, 3D Smart Clean, 3D Excel Clean and (new!) the 3D Samba Clean. All these blast cabinets, depowdering units, comply with ATEX legislation, class II 3/-D T125˚. In addition, customer-specific Normfinish blast cabinets can also be developed.